Description

Aprica Machine Steel Backing Plates

Solid steel CNC Machined/Threaded Backing Plates ready to use

You pick what you want, please have a good look at the measurements for each size plate.

Note: These plates MAY or MAY NOT require a little work to fit depending on machine.

Sizes are for Myford and Boxford lathes, but these are the most common sizes and will fit on many other Lathes as long as the OD and TPI is the same on your spindle nose, if in doubt email us at

lprtools@bigpond.com or contact us on 0357841351

We do sell unmachined plates in 4", 5" & 6" please see our store for those.

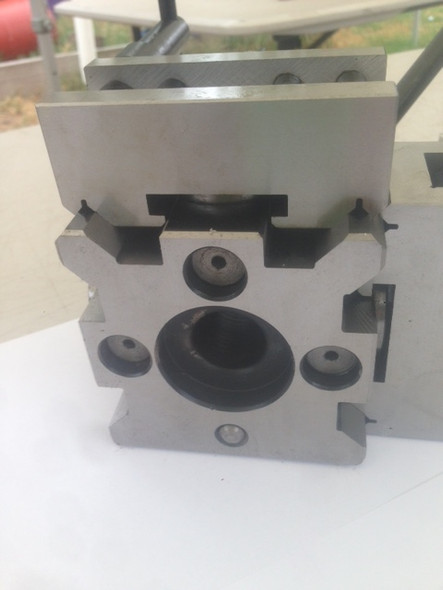

Sizes available:

4” OD with 1.3/4" Boss - Thread size 1.1/8” x 12 TPI

5” OD with 1.3/4" Boss - Thread size 1.1/8” x 12 TPI

5” OD with 2" Boss - Thread size 1.1/2” x 8 TPI

6” OD with 2" Boss - Thread size 1.1/2” x 8 TPI

Here is a general guide when deciding if a backing plate will suit your hercus:

-

Determine the spindle nose thread size: The first step in getting a backing plate to fit your Hercus machine is to determine the spindle nose thread size. The Hercus lathe, for example, has a 1 1/2" x 8 TPI spindle nose thread. Check your Hercus machine manual or consult a Hercus dealer to confirm the spindle nose thread size for your specific machine.

-

Choose a compatible backing plate: Once you know the spindle nose thread size, you can choose a compatible backing plate. Hercus lathes typically use backing plates with a 1 1/2" x 8 TPI thread, but you should confirm this before making a purchase.

-

Check the fit: Once you have your new backing plate, check to ensure it fits your Hercus machine spindle. Remove any chucks or attachments that may be on the spindle, then screw the backing plate onto the spindle. Ensure it is threaded on tightly and does not wobble or move.

-

Mount the chuck: Once you have confirmed the fit of the backing plate, you can mount your chuck onto the plate. Ensure that the chuck is securely attached to the backing plate, and tighten any screws or bolts that are used to hold the chuck in place.

-

Test the setup: Once the chuck is attached, test the setup by turning on the lathe and running it at a low speed. Observe the workpiece as it rotates, checking for any wobbling or vibration. If there is any wobbling or vibration, stop the lathe and check the fit of the backing plate and chuck. Make any necessary adjustments before continuing.

-

Start your work: Once you have confirmed that the backing plate and chuck are properly attached and running smoothly, you can begin your work.

Overall, getting a backing plate to fit your Hercus machine requires determining the spindle nose thread size, choosing a compatible backing plate, checking the fit of the backing plate, mounting the chuck, testing the setup, and then starting your work. With a bit of patience and attention to detail, you should be able to get a perfect fit for your Hercus machine.