Description

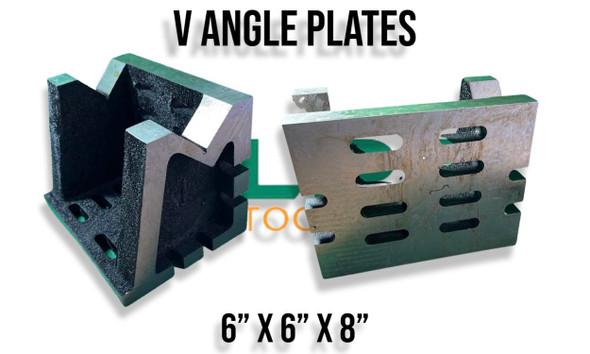

PRECISION CAST IRON SLOTTED ANGLE PLATE

Used for quick mounting fixtures for machine set-up, layout, or inspection. Manufactured from good quality seasoned casting. Properly hardened & ground from all the sides. Properly Machined 900 Square.

Size 4/1/2" x 3-1/2" x 3"

Increasing the effective size of an angle plate

An angle plate can be made larger by bolting a flat plate or rectangular tube onto the front of it. If some rectangular tube is used allowance has to be made for the tube bending slightly under pressure. One solution to this is to fit the nut onto the bolt inside the tube on the side where something is being clamped to the tube.

Use of angle plate on end

Though it would be usual to use two large surfaces on an angle plate the ends of the two sides are always flat and at right angles to the two sides. This end surface could be mounted on the milling table. It would have to be clamped to the table. The possible advantage of this is that very often the length of an angle plate is longer than the height of either of its sides.

Use of an angle plate for aligning

An angle plate can be seen as being equivalent to a square but of much greater thickness. Because of this it can be used to align two edges at right angles but where one is at a different height to the other.

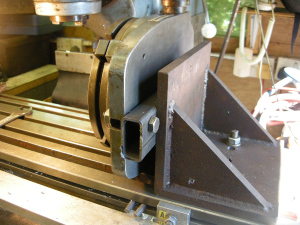

Use of an angle plate as a stop

An angle plate bolted to the milling table to one side of a vice can be used as a stop when holding a workpiece in the vice.

Angle plate used to mill accurate angles

One advantage of mounting a workpiece on an angle plate compared to using a tilting vice is that it can be used to mill one surface at an angle to another.

The workpiece can be mounted using clamps on the angle plate using a precision protractor. All of this can be done while the surface being used is horizontal.

![Slotted Mini Angle Plate [3" x 2" x 2.1/2"] Slotted Mini Angle Plate [3" x 2" x 2.1/2"]](https://cdn11.bigcommerce.com/s-c9l4hm6h/images/stencil/590x590/products/4671/14198/Mini_Angle_Plate_-_3inch__98577.1705637772.jpg?c=2)